The percast concrete manhole covers & frames were introduced to the construction industries due t the necessity of suitable alternative to cast iron manhole covers & frames. The cost of cast iron is increasing day by day and cast iron manhole covers are prone to filferage and misuse since they possess a high resale value, causing financial loss due to the need for According to of stolen covers, accidents due to the open manhole and other environmental problems.

MERITS OF PRECAST CONCETE MANHOLE COVER/ FRAME OVER CI COVER / FRAME

| CHARACTERSTICS | C I COVERS | PRECAST CONCRETE COVERS |

|---|---|---|

| Strength | Equal | Equal |

| Scr p Value | High | Very low |

The raw materials are being used in manufacture of Precast Concrete Manhole cover and frame are according to the specification of IS: 12599 : 2002

Cement: Cement used for the precast concrete manhole covers shall confirm to IS 269 or IS 455 or IS 1489 or IS 1489 or IS 6909 or IS 8041 or IS 8043 or IS 8112 or IS 12330 or IS 12269.

Aggregates: The Aggregate are well graded. The nominal maximum size of coarse aggregate is not exceeding 20mmm, which confirms to the requirement of IS383.

Concrete: The minimum cement content in the concrete shall be 360 kg/ m3, with a maximum water cement ratio of 0.45. Concrete weaker than grade M-30 is not be used. Compaction of concrete shall be done by machine vibration.

MANUFACTURING:

MIXING: Cocrete are mixed in a mechanical mixer to ensure uniform distribution of materials and the mass is uniform in colour and consistency.

DEMOULDING: After According to cover an d frame are protective until they are sufficiently hardened to permit handling without damage.

CURING: The hardened concrete mahole cover and frame are replaced in appliance and tank the period of curing according to Is 456.

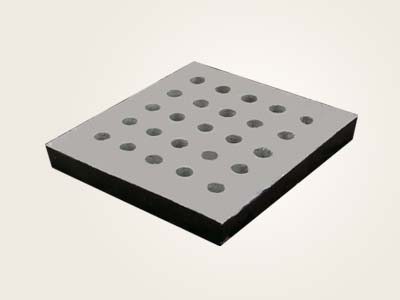

Cover: The underside of covers is treated with anticorrosive paint to prevent any possible damage from corrosion. The top surfaces of the covers are given a chequered finish. Thw covers are casted with a protective mild steel sheet of minimum 2 mm thickness around the periphery of the cover protect the edge of the time of lifting and handling.

Frames: The top outer edge of the frames is protected by 25 mm X 3 mm mild steel flat as part of the frame to prevent from possible damages. The exposed surface of the mild steel flat is given suitable treatment with anticorrosive paint or coating.

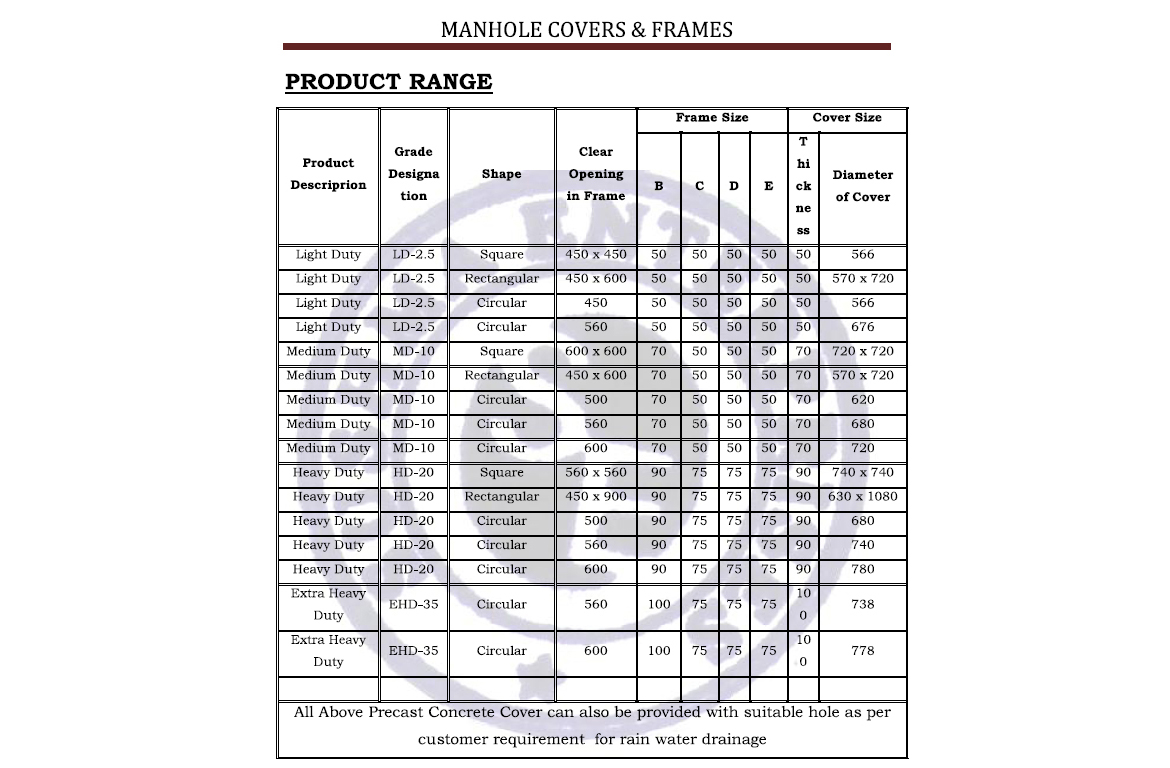

Manhole Covers and Frames shall be of the following four grades and types:

| Grade | Grade Designation | Type/Shape of Cover |

|---|---|---|

| Medium Duty | MD-10 | Rectangular, Square, and Circular |

| Light Duty | LD-2.5 | Rectangular, Square, Circular |

| Heavy Duty | HD-20 | Rectangular (Scrapper Manhole), Square, Circular, and Lamphole |

| Extra Heavy Duty | EHD-35 | Rectangular (Scrapper Manhole), Square, and Circular |