With the development of precast concrete industry, the precast concrete kerbs, channels, edgings, quadrants ands gutter aprons gained popularity due to their ease of manufacture and architectural and other considerations. These kerbs are available in a range of sections for use in construction of carriage way and foot ways.

Thr cement used in the manufacture of Kerb stones etc. conforms to IS: 8112- 1976 (43 Grade) or IS: 12269 – 1987 (53 Grade)

All aggregate used in manufacture conforms to the requirements of IS: - 383 – 1970. The aggregate abrasion value, crushing value, impact value also comply to the IS: - 383 – 1970. Aggregate got tested from outside authorized laboratory and monthly sieve analysis is also carried out in our factory laboratory for particle than one fourth of minimum thickness of the section of Kerb.

Minimum M-20 Grade concrete is used, with strength requirement specified in industrial floors.

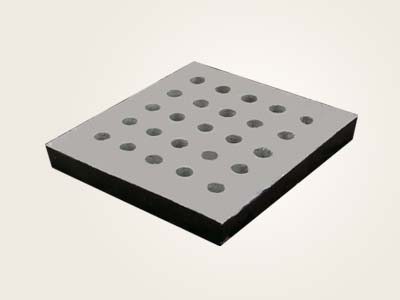

The kerb stone are manufactured in different section and lengths.

The kerbs stones are manufactured in different section and length.

The Kerbs are manufactured under strict quality control and proper finish to the surface of kerbs is provided by using marble power. Permitted coloring pigments may also be added for attractive colors of Kerbs.

The Kerbs are manufactured by hydraulic and vibrator process. The pressure applied for compression of concreted is very high, 7 Nm/mm2. The escape of the finer particle of cement during the process of pressuring is prevented.